Solid Surface is a unique, high-quality, versatile material which has a wide range of uses in bathrooms, kitchens and furniture, as well as for designs in restaurants, hotels, airports, shop-fittings and facades, among others.

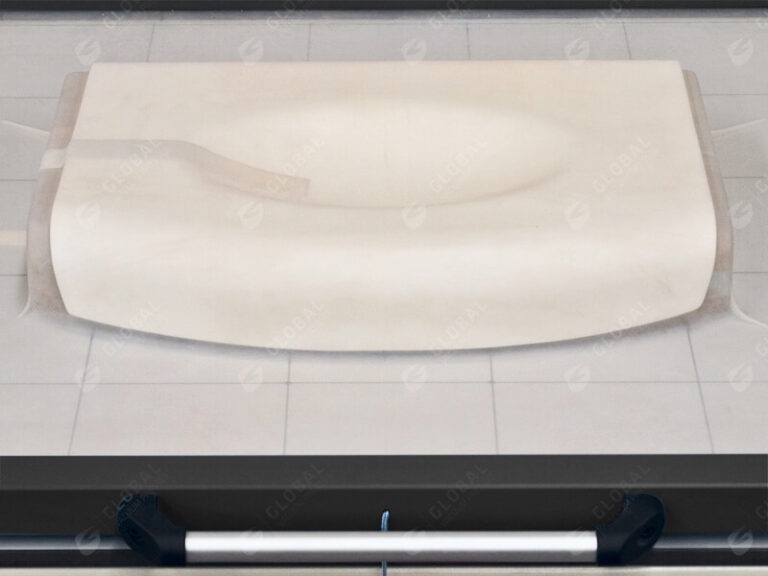

Acrylic materials can be thermoformed into 2D curved shapes or spectacular 3D designs and can be machined with the standard hard metal wood tools. There are two steps in the thermoforming process: preheating and pressing.

Want to see how our thermoforming stations form Acrylic materials? Click the button below to see the full process with our Global Duo Professional.