In the year 1991, a company was born that would reshape the landscape of the vacuum press industry: Global Vacuum Presses. Founded by visionaries Anton Nabuurs and Teresa Ramirez, this company has become a benchmark for innovation and quality in the realm of industrial presses.

From its inception, Anton and Teresa shared a bold vision of creating machinery that would revolutionize industrial processes. With a unique blend of skills and knowledge, these entrepreneurs set out to develop cutting-edge technologies that would surpass market expectations.

The early years of Global Vacuum Presses were marked by the tireless dedication of its founders. Anton Nabuurs, with his profound technical expertise, brought the precision engineering needed to design state-of-the-art vacuum presses. Meanwhile, Teresa Ramirez, with her experience in business management, laid a solid foundation for the company’s growth and expansion.

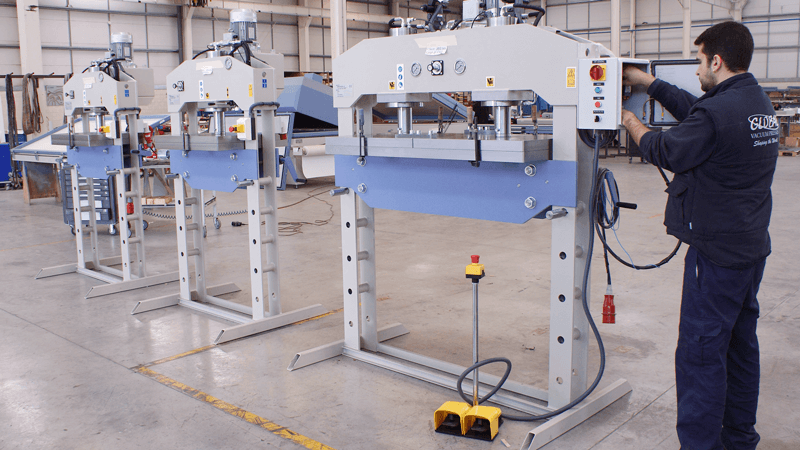

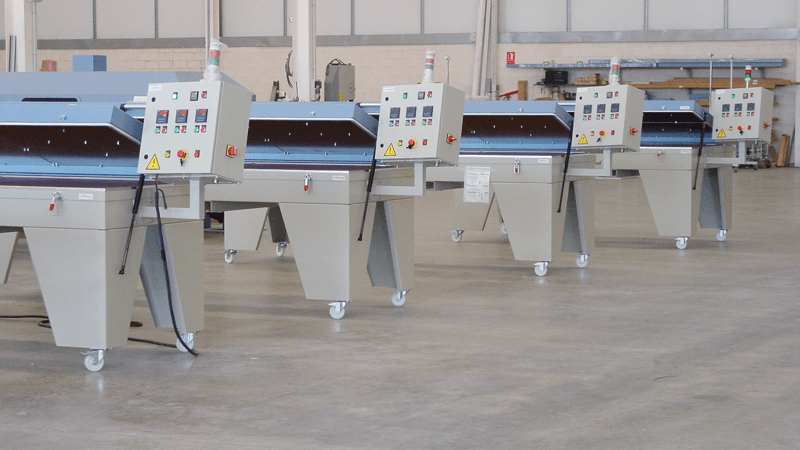

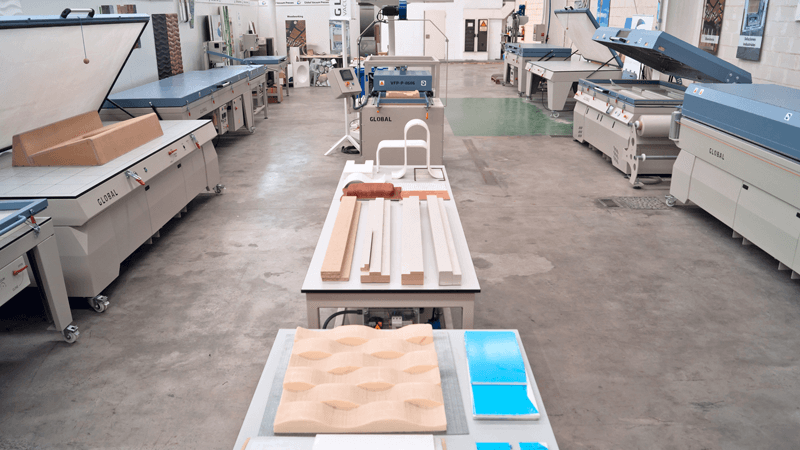

As Global Vacuum Presses grew, so did its reputation. The company stood out for its commitment to quality, innovation, and customer satisfaction. Its vacuum presses became essential in various industries, from furniture manufacturing to the production of electronic components.

In the early years of the new millennium, Global Vacuum Presses solidified its position as a market leader. The company continued to invest in research and development, incorporating technological advancements to enhance the efficiency and versatility of its products.

Anton and Teresa’s vision extended beyond commercial success to encompass social and environmental responsibility. Global Vacuum Presses implemented sustainable practices in its manufacturing processes and actively participated in community initiatives, establishing a legacy of corporate responsibility.