The Vacuum Press Industrial is designed to meet the demands of automatic and continuous production cycles with process monitoring, with its advanced features enabling high-quality work.

The vertical vacuum press is equipped with a PLC automation system operated by touchscreen display. The software offers fully-manual control and automatic production mode by time or temperature, which can be customised to meet the individual requirements of the customer. The vertical lifting/lowering system of the membrane frame prevents materials from sliding over the mould while closing the membrane frame and offers access from all sides, which is particularly important when pressing large, complicated 3D shapes. The specific temperature sensor provides optimal production monitoring and controls the automatic temperature mode. In addition, the adjustable air turbines accelerate the cooling process. The membrane frame can be easily changed in under two minutes, allowing a high-volume membrane to be mounted for large objects.

The vacuum press for continuous production cycles and consistent production quality

Model

VP-I-3114

VP-I-3116

VP-I-3714

VP-I-3716

Press area

3140 x 1420 mm

3140 x 1620 mm

3740 x 1420 mm

3740 x 1620 mm

Operation

PLC operated with touchscreen control

Manual operation and automatic mode

Production cycles by time and temperature

Hydraulic lifting-lowering system (vertical opening)

Vacuum pump

100 m3/h vacuum pump

Rotary vane, oil-free

Pressure switch (Auto power ON/OFF)

Max. pressure

8.5 t/m2 = 150 mbar abs.

Membrane

Natural rubber, 2mm

Silicone, 2 mm

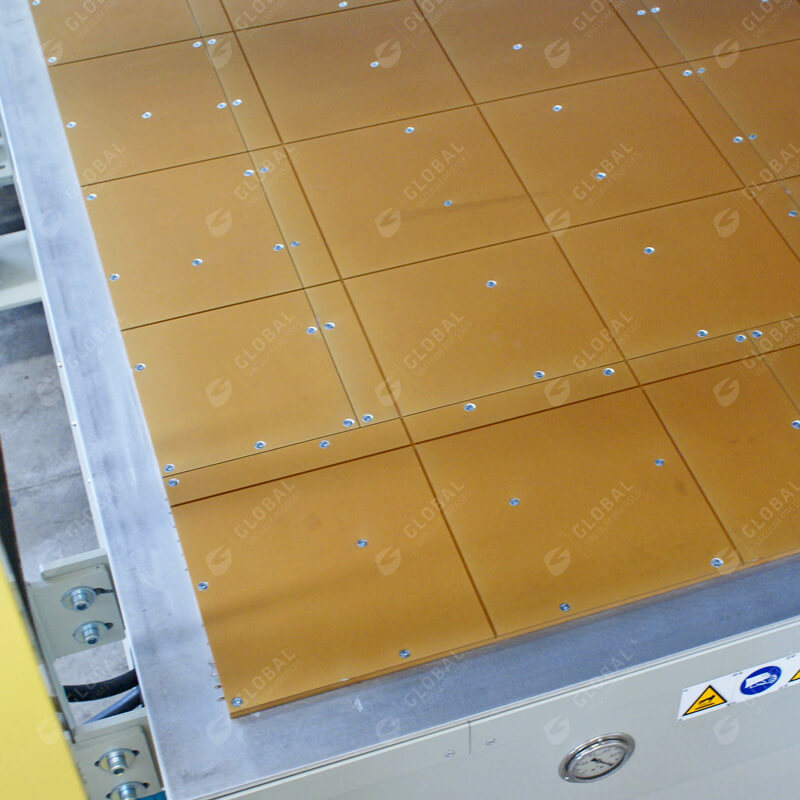

Work top

18 mm wear-resistant HPL compact board

Integrated PT100 temperature sensor

Grid line raster for even air evacuation

Working height ±900 mm

Supports

Adjustable anti-slip feets

Security system

Passive security bars

Emergency Stop

Elec. connection

220/400V, 3~, 50/60 Hz

Max. power

7.0 kW

Dimensions

3670 x 1830 x 2000 mm

3670 x 2030 x 2000 mm

4270 x 1830 x 2000 mm

4270 x 2030 x 2000 mm

Weight

1270 kg

1395 kg

1360 kg

1496 kg

Certification

CE – Declaration of conformity

CO – Certificate of origin (on request)

Technical information may differ slightly.