The Global Compact vacuum membrane press is designed to provide a small and easy-to-use vacuum press at an affordable price. The system consists of the vacuum membrane press and an individual vacuum pump, mounted on a portable chassis.

This compact vacuum membrane press is available with or without the vacuum pump, which can also be connected to all Global vacuum bags. The vacuum press is ideal for the production of small work objects such as flat or shaped wooden parts, thermoforming solid surfaces and thermoplastic materials.

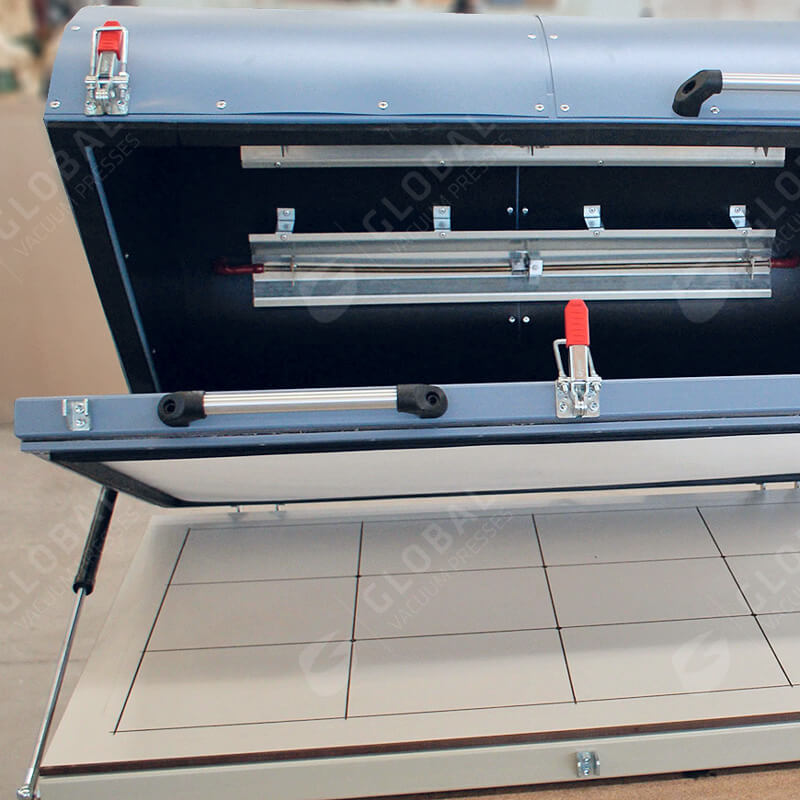

The well-proportioned press area of 1020 x 620 mm, the ease of use, the space-saving design and its great versatility at an affordable price make it ideal for educational institutions, instrument makers, woodwork restoration and creative designers.

Benchtop vacuum membrane press for veneering, laminating and bending small components

Model

VP-C-1006

Press area

1020 x 620 mm

Operation

Manual operation

Vacuum pump switch ON / OFF

Vacuum release valve

Vacuum pump

8 m3/h vacuum pump

Rotary vane, oil-free

Max. pressure

8.5 t/m2 = 150 mbar abs. (85% Vacuum)

Membrane

Natural rubber, 2 mm

Silicone, 2 mm

Work top

13 mm wear-resistant HPL compact board

Grid line raster for even air evacuation

Working height 75 mm

Elec. connection

110/230V, 1~, 50/60 Hz

Max. power

0.25 kW

Dimensions

1180 x 788 x 132 mm (Press)

330 x 205 x 260 mm (Pump)

Weight

50 kg (Press)

16 kg (Pump)

Certification

CE – Declaration of conformity

CO – Certificate of origin (on request)

Technical information may differ slightly.