The Global Thermofoil vacuum forming press is developed for the 3D foil lamination of rigid thermoplastic deco foils and thin plastic sheets used for the production of kitchen cabinet doors, panels and other furniture parts.

The Thermofoil press is distinguished by its quartz heating elements, which ensure a fast response and high efficiency, resulting in time and energy savings. The 3 independently controllable heating zones ensure uniform heating and control, especially for vacuum forming of advanced shapes and materials. In addition, the powerful oil-lubricated vacuum pump delivers top quality performance for highly detailed 3D foil lamination processes.

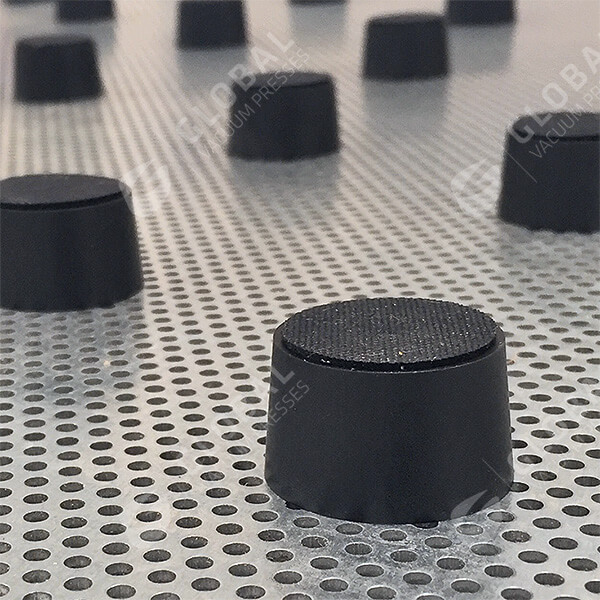

The 3D thermofoil laminating press is equipped with a PLC automation system operated by touchscreen interface, which offers the possibility of temperature curves, vacuum pressure steps and user programme settings. An easy-to-use magnet pin system saves time and money in the production of 3D foil wrapped parts, eliminating the conventional mdf boards.