The Global Duo Industrial thermoforming station is designed for continuous production quality, guaranteed by process monitoring of automatic production cycles. The Duo Industrial combines a vacuum membrane press with vertical opening-closing system and pre-heating oven in one smart machine design, controlled by a PLC and operated by touchscreen display.

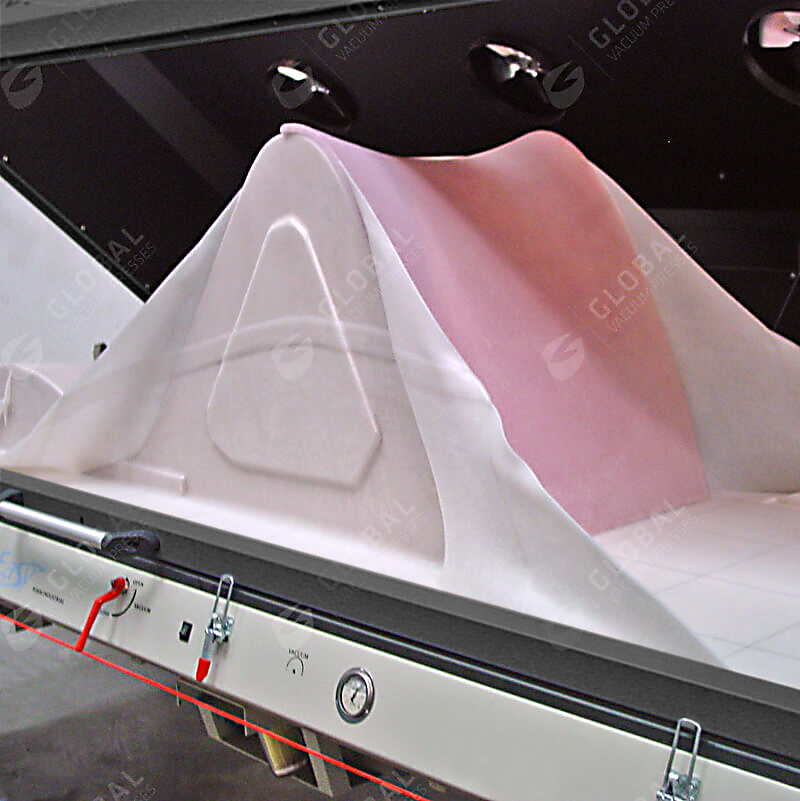

The operator software offers full manual control and automatic production mode cycles, which can be set by time or temperature according to the individual requirements of the object in question. The vertical lifting-lowering system of the membrane frame prevents materials from sliding over the mould while closing the membrane frame and offers easy access from all sides. The membrane frame can be easily changed in under 2 minutes, allowing a switch to a high-volume membrane frame for large objects, or a 3D vacuum forming frame for thermoplastics.

The bottom-mounted heating oven with electric aluminium heating platen guarantees uniform heating throughout the entire thickness and surface of the material. During the pre-heating process, the material is placed onto the heating platen and the insulated cover ensures energy savings and uniform heating.