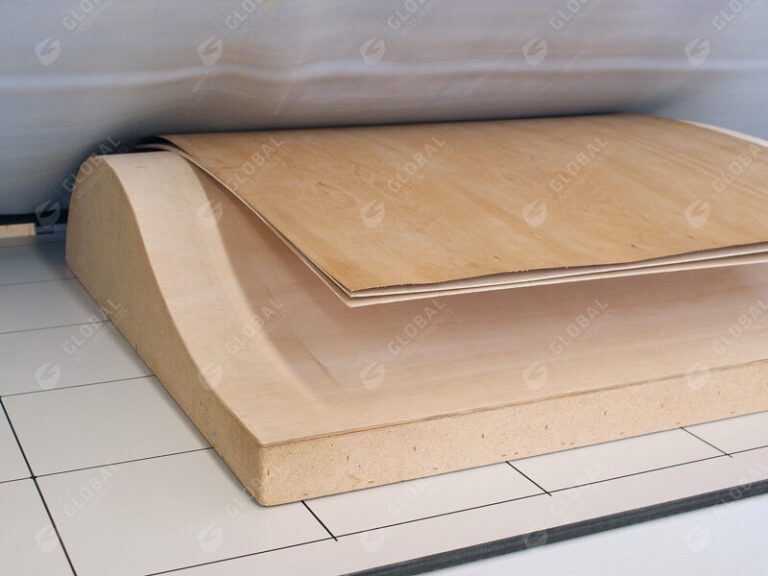

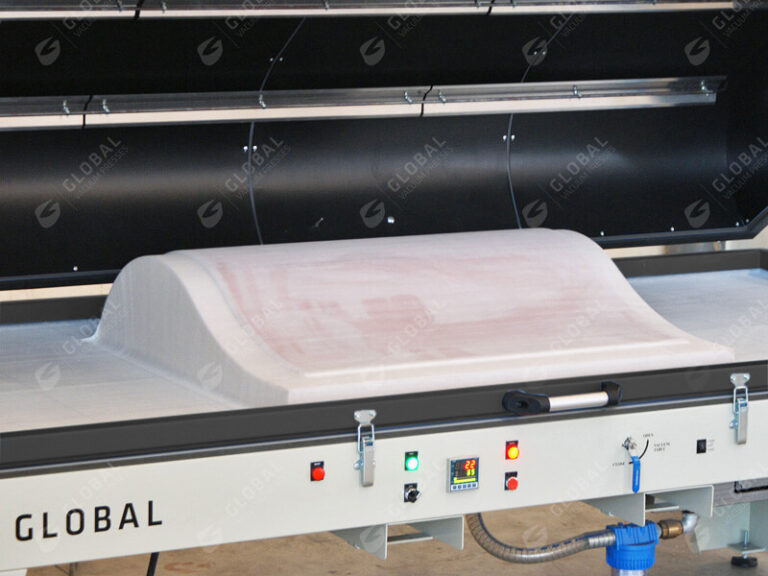

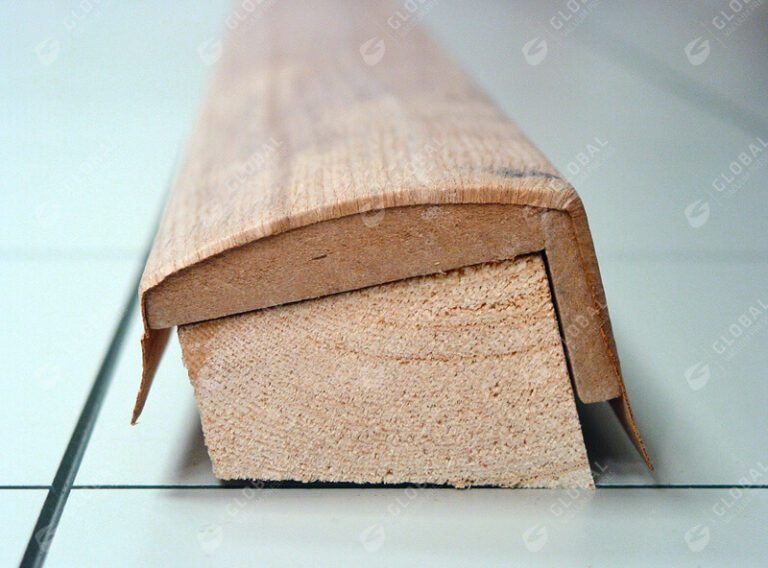

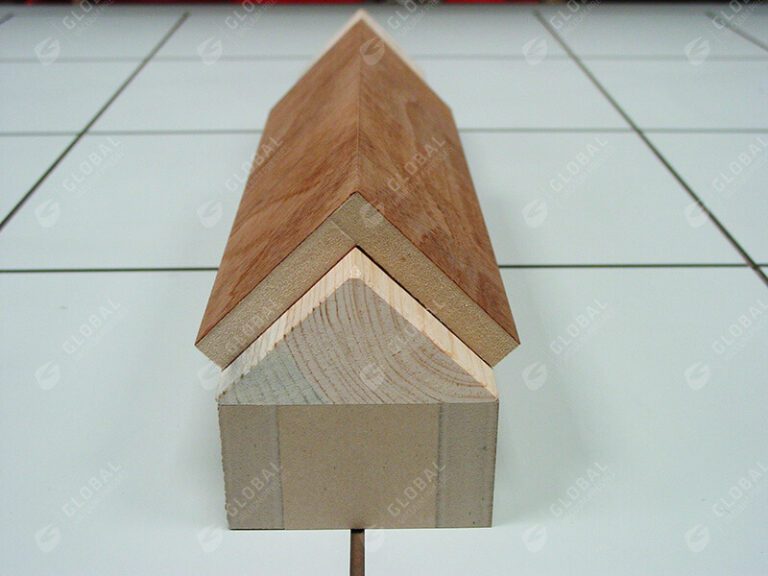

In the woodworking industry, there are vacuum presses which are designed for vacuum pressing curved laminated shapes, which is often referred to as bent lamination or form veneering. This form of pressing is undoubtedly the primary application of Global vacuum membrane presses, though there are of course other applications than the woodworking industry such as flat pressing, laminating of HPL decors and veneers, profile veneering, and glueing of solid wood, among others.

Wood veneers with rigid or flexible boards are the materials traditionally used to create flat and shaped wooden components. These days, new materials such as foamed plastics and honeycomb structures are used as a core material, while modern finishes such as HPL decors, aluminium, leather, textiles, flexible natural stone and plastic materials enable the creation of distinctive new products that are elegant, lightweight, convenient and stable.